Bolt Sizes Chart

Fasteners such as bolts, screws, and nuts are used in everyday construction to bring two surfaces (vinyl, wood, or metal) and bind them together. Their threads make them easy to install and remove, making them incredibly convenient.

To take advantage of the convenience these fasteners offer, you need to match them accordingly based on their sizes. When choosing bolts, you will encounter different sizes and types, and this article will help you select the right size for your construction project.

| Size | Nominal (Major) | Coarse Thread (UNC) | Fine Thread (UNF) | ||||

| Diameter [in] | Threads Per Inch | Tensile Stress Area [in2] | Minor Area [in2] | Threads Per Inch | Tensile Stress Area [in2] | Minor Area [in2] | |

| #0 | 0.06 | --- | --- | --- | 80 | 0.0018 | 0.0015 |

| #2 | 0.086 | 56 | 0.0037 | 0.0031 | 64 | 0.0039 | 0.0034 |

| #4 | 0.112 | 40 | 0.006 | 0.005 | 48 | 0.0066 | 0.0057 |

| #5 | 0.125 | 40 | 0.008 | 0.0067 | 44 | 0.0083 | 0.0072 |

| #6 | 0.138 | 32 | 0.0091 | 0.0075 | 40 | 0.0102 | 0.0087 |

| #8 | 0.164 | 32 | 0.014 | 0.012 | 36 | 0.0147 | 0.0129 |

| #10 | 0.19 | 24 | 0.0175 | 0.0145 | 32 | 0.02 | 0.0175 |

| 1/4" | 0.25 | 20 | 0.0318 | 0.0269 | 28 | 0.0364 | 0.0326 |

| 5/16" | 0.3125 | 18 | 0.0524 | 0.0454 | 24 | 0.058 | 0.0524 |

| 3/8" | 0.375 | 16 | 0.0775 | 0.0678 | 24 | 0.0878 | 0.0809 |

| 7/16" | 0.4375 | 14 | 0.1063 | 0.0933 | 20 | 0.1187 | 0.109 |

| 1/2" | 0.5 | 13 | 0.1419 | 0.1257 | 20 | 0.1599 | 0.1486 |

| 9/16" | 0.5625 | 12 | 0.182 | 0.162 | 18 | 0.203 | 0.189 |

| 5/8" | 0.625 | 11 | 0.226 | 0.202 | 18 | 0.256 | 0.24 |

| 3/4" | 0.75 | 10 | 0.334 | 0.302 | 16 | 0.373 | 0.351 |

| 7/8" | 0.875 | 9 | 0.462 | 0.419 | 14 | 0.509 | 0.48 |

| 1" | 1 | 8 | 0.606 | 0.551 | 12 | 0.663 | 0.625 |

| 1-1/8" | 1.125 | 7 | 0.763 | 0.693 | 12 | 0.856 | 0.812 |

| 1-1/4" | 1.25 | 7 | 0.969 | 0.89 | 12 | 1.073 | 1.024 |

| 1-3/8" | 1.375 | 6 | 1.155 | 1.054 | 12 | 1.315 | 1.26 |

| 1-1/2" | 1.5 | 6 | 1.405 | 1.294 | 12 | 1.581 | 1.521 |

| 1-3/4" | 1.75 | 5 | 1.9 | 1.74 | --- | --- | --- |

| 2" | 2 | 4.5 | 2.5 | 2.3 | --- | --- | --- |

Metric Bolt Thread Size:

Thread sizes for coarse and fine pitch thread were created using the standard sizes from ASME B1.13M. Coarse pitch threads are preferred and should be used whenever possible, as stated in ASME B1.13M.

| Nominal (Major) | Coarse Pitch | Fine Pitch | ||||

| Diameter [mm] | Pitch | Tensile Stress | Minor | Pitch | Tensile Stress | Minor |

| [mm] | Area [mm2] | Area [mm2] | [mm] | Area [mm2] | Area [mm2] | |

| 1.6 | 0.35 | 1.27 | 1.076 | --- | --- | --- |

| 2 | 0.4 | 2.073 | 1.789 | --- | --- | --- |

| 2.5 | 0.45 | 3.391 | 2.98 | --- | --- | --- |

| 3 | 0.5 | 5.031 | 4.473 | --- | --- | --- |

| 3.5 | 0.6 | 6.775 | 6 | --- | --- | --- |

| 4 | 0.7 | 8.779 | 7.75 | --- | --- | --- |

| 5 | 0.8 | 14.18 | 12.68 | --- | --- | --- |

| 6 | 1 | 20.12 | 17.89 | --- | --- | --- |

| 8 | 1.25 | 36.61 | 32.84 | 1 | 39.17 | 36.03 |

| 10 | 1.5 | 57.99 | 52.29 | 1.25 | 61.2 | 56.3 |

| 12 | 1.75 | 84.27 | 76.25 | 1.25 | 92.07 | 86.04 |

| 14 | 2 | 115.4 | 104.7 | 1.5 | 124.5 | 116.1 |

| 16 | 2 | 156.7 | 144.1 | 1.5 | 167.2 | 157.5 |

| 20 | 2.5 | 244.8 | 225.2 | 1.5 | 271.5 | 259 |

| 24 | 3 | 352.5 | 324.3 | 2 | 384.4 | 364.6 |

| 30 | 3.5 | 560.6 | 519 | 2 | 621.2 | 596 |

| 36 | 4 | 816.7 | 759.3 | 2 | 914.5 | 883.8 |

| 42 | 4.5 | 1121 | 1045 | 2 | 1264 | 1228 |

| 48 | 5 | 1473 | 1377 | 2 | 1671 | 1629 |

| 56 | 5.5 | 2030 | 1905 | 2 | 2301 | 2252 |

| 64 | 6 | 2676 | 2520 | 2 | 3031 | 2975 |

| 72 | 6 | 3460 | 3282 | 2 | 3862 | 3799 |

| 80 | 6 | 4344 | 4144 | 1.5 | 4851 | 4798 |

| 90 | 6 | 5591 | 5364 | 2 | 6099 | 6020 |

| 100 | 6 | 6995 | 6740 | 2 | 7562 | 7473 |

| 110 | --- | --- | --- | 2 | 9182 | 9084 |

How to Measure Bolt Size

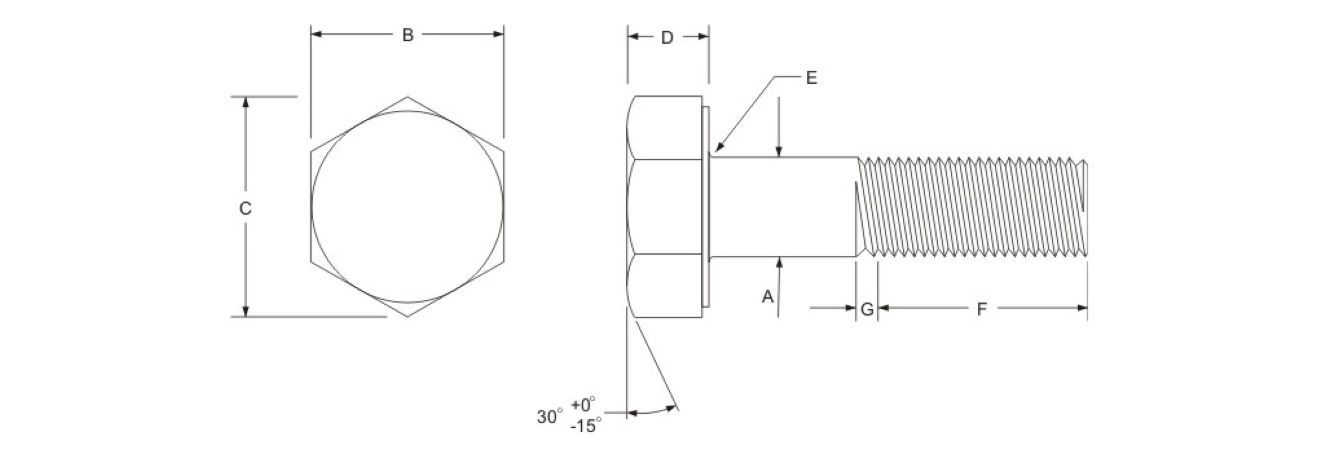

Several kinds of bolts exist, which include Hex bolts, J bolts, T bolts, Anchor bolts, and Flange bolts. A bolt size chart describes its size based on its proportions. These parts are standard across all bolt types and consist of the head and body.

Bolt Head

A bolt’s head is can be round, hexagonal, or square in shape. It has three vital dimensions: size across its flats, size across, its corners, and the head’s height. These dimensions are useful when attempting to tighten or loosen a bolt. A bolt head’s diameter depends on its shank’s diameter.

Bolt Body

The bolt body consists of its shaft with the threaded area. The most important bolt body dimensions to know include:

Bolt diameter

Length

Thread length

Thread pitch

The bolt diameter is the main size considered and it is measured across the bolt shank or its threaded area. Its length is measured from its tip to the point where its shank meets the head. If the bolt has threads, the threaded area is also included in this measurement.

A bolt’s thread pitch in the imperial system is described as a measure of the number of threads it has per inch, while in the metric system, it is described as the distance between two adjacent threads. When we say ‘bolt size’, we mean the diameter of the bolt shank. Thread pitch can be further described as coarse or standard, fine, or super fine. Coarsely threaded bolts tend to have lower thread counts and are popularly used in general applications. For applications requiring greater holding force, you can use finely threaded bolts. Pitch combinations that seem to be in the middle can simply be described as ‘fine pitch.’ The bolt head size is often only used to determine the wrench to use when tightening or loosening the bolt.

Grade or Class

The term ‘grade’ is used in the imperial system, while ‘class’ is used in the metric system. Still, both terms describe the tensile strength of a bolt, which is the maximum stress it can handle before it snaps.

In the USCS imperial system, a bolt’s tensile strength is usually indicated on its head using grade marks. These marks are radial lines; the more lines on the bolt, the greater its strength. In the metric system, its class is indicated via a class number that is imprinted on the bolt head. Again, the greater the number, the greater the stress the bolt can handle. If you spot another number next to the class, for instance, 10.8, this number is called the ‘yield strength.’ The yield strength describes the level of stress it can take before it is bent past the point of no return to its original shape.